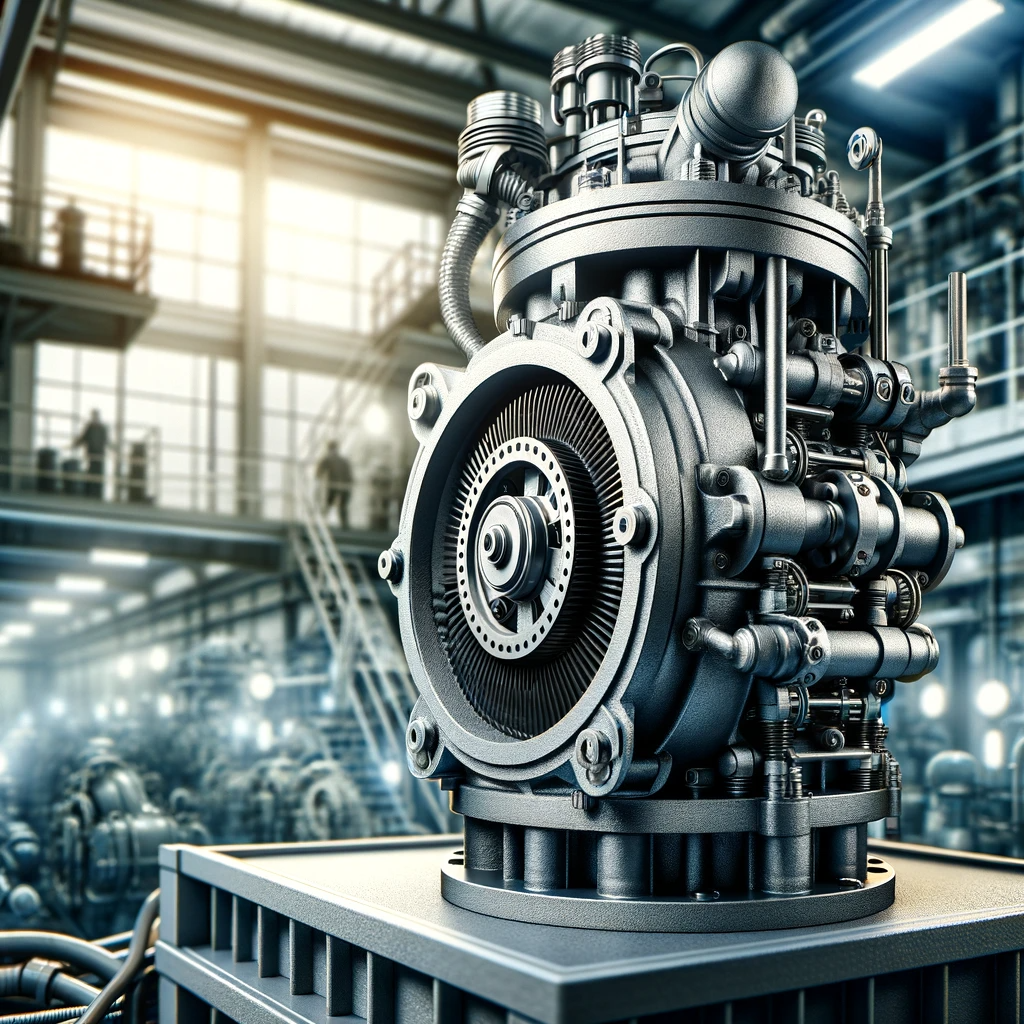

Homa Submersible Pumps: The Industrial Powerhouse for Water Management is a renowned company known for its high-quality engineering and adherence to strict standards in the manufacturing process of their pumping equipment. Homa pumps are designed to deliver exceptional performance, reliability, and durability. With a wide range of pumps and motors to choose from, Homa ensures that their products meet the diverse needs of various industries and applications. The series line includes non-clog pumps that can handle wastewater, sewage, solids, effluent, liquids, and even fibers. Equipped with multi-vane impellers or vortex motors, Homa pumps provide efficient operation in different locations. Whether it’s the TP53 series or the HOMA H 300, Homa Submersible Pumps are the go-to choice for industrial wastewater management.

Fundamentals of Homa Submersible Pumps

Homa Submersible Pumps, known as the industrial powerhouse for water management, offer a diverse series of pumps that cater to various pumping needs. With features like vortex impellers, explosion-proof variants, and efficient solids passages, the AK, AKX, and AV ranges provide unmatched performance. These pumps are equipped with class H insulation and hold FM approval for group C applications. Designed for pit installations, they feature temperature sensors and leak detection for enhanced safety. Homa Submersible Pumps are the standard for reliable and durable operation, minimizing downtime and ensuring efficient water management in the wastewater industry.

Homa Pump Technology is backed by a robust network of service centers and distributors, making them easily accessible to customers. With a focus on preventing overheating of the pump motor, Homa Submersible Pumps find applications in various industries, including engineering, installation, and maintenance. The company’s state-of-the-art test center, known as “Nick,” ensures the quality and performance of each pump before it reaches the customers. Homa Submersible Pumps are the go-to solution for efficient and reliable pumping, offering advanced technology and engineering expertise in water management.

Various Applications of Homa Submersible Pumps

Homa Submersible Pumps: The Industrial Powerhouse for Water Management has a wide range of applications in the water industry. From replacements and product solutions to service and maintenance, Homa Submersible Pumps are trusted by water management facilities across the globe. For instance, in Ansonia, Connecticut, Homa’s workshop and warehouse facility is equipped with the latest design and manufacturing tools. Their experienced staff, including sales experts and pump technicians, are dedicated to providing the best product selection and support for all your wastewater handling needs. Whether it’s equipment upgrades or new pump purchases, Homa Submersible Pumps is the go-to team for all water management projects.

The Homa Submersible Pumps series offers a variety of options to meet different pumping requirements in industrial wastewater management. One of their notable products is the TP53 series, known for its energy efficiency and reliable operation. Ranging from 1 HP to 500 HP, Homa’s TP53 series pumps are designed with the highest FM class for safety and durability. Additionally, Homa’s Submersible Wastewater pumps are ideal for lift stations and other wastewater handling applications. With their expertise in pump technology and water management, the team at Homa is ready to assist you with any symptom or operation-related issue at your facility. Contact Homa Submersible Pumps for all your pumping needs and experience the industrial powerhouse in water management.

The Unique Benefits of Homa Submersible Pumps

Homa Submersible Pumps: The Industrial Powerhouse for Water Management offers a wide range of unique benefits. The grinder pumps and motors of Homa’s products ensure efficient and reliable wastewater management. With their diverse product range, Homa can cater to various delivery requirements, including pump retrofits installations. Homa pumps also feature class and division certifications, making them suitable for a wide range of applications. The use of channel impellers and advanced pump technology minimizes pump clogs and maximizes wastewater station efficiency. Furthermore, Homa’s inventory ensures quick deliveries in case of emergencies. The lifecycle efficiency of Homa pumps, combined with their robust construction and ability to handle high total dynamic head (TDH), make them the preferred choice for various water management scenarios. With their knowledgeable engineering and customer support, Homa provides comprehensive solutions for all wastewater pumping needs. For more information, contact Homa Pump Technology.

Energy Efficiency and Environmentally Friendly Design

Homa Submersible Pumps: The Industrial Powerhouse for Water Management is a leading brand known for its energy efficiency and environmentally friendly design. When it comes to thoughts of reducing energy consumption and minimizing harm to the environment, Homa Submersible Pumps tops the list. From the content of the materials used in their pump systems to the packaging and even the operating costs, Homa is committed to sustainability. Their pump systems are designed to minimize energy use while maximizing station reliability. By implementing best practices and utilizing innovative technologies, Homa Submersible Pumps ensures that water utilities and other industries can efficiently manage water without compromising the environment.

Homa Submersible Pumps: The Industrial Powerhouse for Water Management is renowned for its dedication to energy efficiency and environmentally friendly design. Their range of submersible wastewater pumps, including the TP53 series and Homa H 300, exemplify their commitment to sustainability. These pumps are designed to minimize energy consumption, with models ranging from 1 HP to 500 HP and meeting FM class ν energy standards. Homa Pumpenfabrik incorporates advanced technologies such as silicon-carbide seals, adapter brackets, and efficient impeller designs to optimize pump performance. Whether it’s for open-air applications or wastewater scenarios, Homa Submersible Pumps are the go-to choice for industries in need of reliable and energy-efficient pumping solutions.

Durability and Longevity of Homa Pumps

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, are known for their exceptional durability and longevity. These pumps are designed to withstand the most demanding environments and perform reliably over extended periods. Whether it’s the TP53 series or the HOMA H 300, Homa Submersible Pumps have proven their efficiency and reliability in pumping industrial wastewater. Equipped with energy-efficient IE3 premium efficiency motors ranging from 1 HP to 500 HP, these pumps are built to last. This level of durability ensures that Homa Submersible Pumps can effectively handle the rigorous demands of water management, reducing downtime and maintenance costs for businesses.

One of the main challenges in water management is preventing sanitary sewer overflows (SSOs) caused by debris and other factors. Homa Submersible Pumps address this problem by offering a range of solutions. With the ability to handle a wide range of flow rates, Homa pumps effectively manage wastewater by preventing blockages and controlling the flow. By incorporating advanced features like variable frequency drives (VFD), these pumps can optimize performance and mitigate the risk of SSOs. The misconception that wastewater pumps are prone to failures is far from the reality when it comes to Homa Submersible Pumps. Their robust design and innovative technologies help businesses avoid fines and penalties while protecting the environment and public health. Investing in Homa Submersible Pumps for water management not only solves current challenges but also pays long-term dividends in terms of efficiency and sustainability.

Detailed Exploration of Homa Submersible Pumps Series

An essential part of understanding the Homa Submersible Pumps series is delving into its detailed exploration. Homa Submersible Pumps, known as the industrial powerhouse for water management, provide reliable performance in various applications. The series includes models such as the TP53 series and the HOMA H300. These cast iron submersible pumps are designed to handle industrial wastewater and drainage efficiently. With a wide range of sizes available, from 1 HP to 500 HP, the Homa Submersible Pumps series can meet the demands of different water management scenarios. The innovative design and energy-efficient features of Homa pumps make them the preferred choice for wastewater treatment plants, package plants, and other water-related industries. These pumps not only save energy but also reduce maintenance costs. To overcome cooling concerns, Homa’s design engineers have implemented various workarounds, ensuring optimal pump performance. In addition to water management, Homa Submersible Pumps are also used in fluid processing and control applications. With their exceptional performance and durability, Homa Submersible Pumps are the go-to choice for businesses seeking efficient and reliable water management solutions.

Characteristic Features of Different Homa Pump Models

Homa Submersible Pumps: The Industrial Powerhouse for Water Management offers a range of pump models with distinct characteristic features. These pumps are designed to handle various pumping needs, including water clearance and drainage. The different models cater to specific water specifications, with motor power ranging from 1 HP to 500 HP. The seals used in the pumps are made of viton, ensuring durability and resistance against high temperatures. The motor housing and motor housing cover are made of cast iron, providing excellent heat dissipation. With their advantage of easy installation and maintenance, these Homa pump models are a reliable solution for industries such as laundries, car washes, and food industries.

For the HOMA H 300 model, the motor housing, cable, rotor shaft, impeller, and screws are all made of stainless steel, ensuring longevity and resistance to corrosion. The seal kit used in this model is made of silikon, which can withstand high temperatures. The oil used in the motor is insulated class H, providing protection against high temperatures. The pump is also equipped with protection IP, safeguarding it from dust and water ingress. With its energy-efficient design, the HOMA H 300 is a reliable submersible pump suitable for industrial wastewater pumping applications.

Suitable Usage Scenarios for Different Homa Pump Models

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, offers a wide range of pump models that are specifically designed for various applications. The housing and suction cover of these pumps are constructed using high-quality materials, ensuring durability and long-lasting performance. Installation of these pumps is suitable for both dry pit and wet well applications. The pumps can effectively operate in sumps with varying water levels, thanks to the float switch control feature. With their multi-vane impellers and vortex design, the pumps can handle solids, effluent, liquids, and even fibers with ease. These pumps are available in different series, including the non-clog pumps, making them ideal for pumping wastewater, sewage, and other challenging liquids.

The Homa Submersible Pumps series line also includes explosion-proof variants, making them suitable for hazardous locations. The pumps are equipped with vortex impellers, which allow for the passage of solids without clogging. The AK and AKX series offer a wide range of pumps that can handle various applications, from residential to industrial wastewater. The AV series, with its Class H insulation and FM approval, is designed for pumping liquids that contain flammable substances such as Group C. With Homa Submersible Pumps, you can trust that your water management needs will be efficiently met, whether it is for residential, commercial, or industrial purposes.

Troubleshooting and Maintenance of Homa Submersible Pumps

Homa Submersible Pumps: The Industrial Powerhouse for Water Management offers a wide range of pumps suitable for various applications in the trade and industry sectors. When it comes to troubleshooting and maintenance, it is essential to follow standard guidelines to ensure optimal performance and longevity of the pumps. Regular checks should be conducted on fm, pit installation temperature, sensors, and leakage to identify any potential issues. It is also crucial to pay attention to the clearance and impeller specifications of the cast iron submersible pumps used for sewage and drainage water. The TP53 series, including the popular HOMA H 300, is designed to handle solids and fibres commonly found in textile applications. Proper maintenance, such as cleaning the pump and motor, checking motor power and flow, and inspecting for any blockage, is necessary to keep the pumps running efficiently. Float switch control can be implemented for automated pump operation. With Homa Submersible Pumps, troubleshooting and maintenance become hassle-free, allowing businesses to focus on their water management needs.

General Troubleshooting Steps for Homa Pumps

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, provide reliable pumping solutions for various industrial wastewater applications. When encountering any issues with your Homa pump, it is important to follow these general troubleshooting steps. Firstly, check the water level in the sump and ensure it is at an appropriate level for the pump to operate effectively. Secondly, inspect the seal kit and replace it if necessary, using high-quality NBR materials for optimal performance. Next, monitor the temperature of the motor and ensure it is within the insulation class H degree. Also, verify that the pump has the appropriate protection IP rating and that the sensor is functioning correctly. Moreover, inspect the impeller and mechanical seal for any signs of wear or damage. Finally, check the housing, siliziumkarbid, stainless steel screws, and rotor shaft for any damage or corrosion, as these materials play a crucial role in the pump’s functionality. By following these troubleshooting steps, you can effectively address any issues and ensure the smooth operation of your Homa submersible pump.

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, are renowned for their exceptional performance in various pumping applications. However, like any mechanical equipment, regular maintenance is crucial for prolonging the lifespan of your pump. To properly maintain your Homa pump, there are a few key steps to follow. Firstly, make sure to perform routine checks on the drainage pump, inspecting for any signs of leaks, unusual noises, or vibrations. Additionally, regularly monitor the start level and ensure the level sensor is functioning properly. Secondly, be mindful of the water quality and avoid pumping corrosive liquids that may damage the pump components. Furthermore, properly clean the pump and remove any debris or sediment that could cause blockages. Finally, ensure the electrical connections, cable, and hose fitting are secure and in good condition. By adhering to these maintenance practices, you can extend the lifespan of your Homa submersible pump and avoid costly repairs or downtime in your water management systems.

Tips for Proper Maintenance and Longer Life of Your Homa Pump

Proper maintenance is crucial for ensuring the longevity of your Homa pump. Regular inspections and servicing will help prevent any potential issues and keep your pump running smoothly. It is important to check the model and code of your pump to ensure you are using the right maintenance procedures and replacement parts. Additionally, be aware of the warranty terms and conditions, as this will help you determine when to seek professional assistance. Regularly monitor the liquid temperature, speed, head, and solids to ensure optimal performance. It is also recommended to inspect the impeller pump, lift shafts, and float switch periodically for any signs of wear or damage. By adhering to these maintenance tips, you can extend the life of your Homa pump and avoid costly repairs.

Homa pumps are known for their advanced pump technology, and proper maintenance helps to maximize their efficiency. When it comes to maintenance, pay attention to the outlet connection, rating, IP rating, and flow rate to ensure they are functioning as intended. Understand the power supply requirements for your specific Homa pump model to avoid any electrical issues. If you require professional assistance, there are service centers and suppliers located throughout the network. The headquarters and factory of Homa Submersible Pumps are based in Connecticut, Ansonia, ensuring quick and efficient service. With a dedicated staff, extensive parts inventory, and prompt delivery, Homa Submersible Pumps stands committed to providing exceptional service and support. Trust Homa pumps to meet the demands of the industrial wastewater industry and keep your operations running smoothly.

Invest in Homa Submersible Pumps: An Informed Decision

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, are a reliable and efficient choice for various pumping needs. With their robust design and advanced engineering, Homa pumps can effectively handle industrial wastewater and other water management requirements. The range of Homa submersible pumps, such as the TP53 series and HOMA H 300, offer a wide selection of options from 1 HP to 500 HP, making it easier to find the right pump for your specific application. These pumps utilize energy-efficient motors and incorporate innovative technology like propeller pumps for maximum performance. Moreover, Homa’s quick turnaround time for deliveries and replacement parts ensures minimal downtime for your operations. When it comes to product choice, purchase, and equipment upkeep, Homa’s sales teams and specialists are well-equipped to assist you in finding the best solutions for your projects. With a dedicated support center and extensive inventory, Homa Submersible Pumps are the preferred choice for many industries, proving their reputation as the industrial powerhouse for water management.

Why Choose Homa Submersible Pumps for Your Business

Homa Submersible Pumps: The Industrial Powerhouse for Water Management. When it comes to choosing the right pumps for your business, Homa Submersible Pumps should be at the top of your list. With their extensive range of products, Homa offers the perfect solution for all your pumping needs. Whether you need to handle solids, wastewater, or dewatering applications, Homa has a pump series that can meet your requirements. Their pumps are designed for easy installation, whether it’s a pit installation or an above-ground setup. Additionally, Homa offers a wide range of motor sizes to ensure that you can find the perfect fit for your specific needs. With Homa pump technology, you can trust in the durability and longevity of their products, making them a reliable choice for your business.

Not only do Homa Submersible Pumps offer exceptional performance and reliability, but they also come with a range of unique features and benefits. Their pumps are designed with energy efficiency and environmentally friendly principles in mind, helping you reduce your carbon footprint while saving on energy costs. The pumps are made with high-quality materials like cast iron (CI) to ensure durability and resistance against corrosion. With advanced technology like silicon-carbide seals and grinder systems, Homa pumps can easily handle tough solids and wastewater applications. Their pumps are also equipped with adapter brackets, allowing for easy replacement and compatibility with existing systems. Furthermore, Homa’s range of mixers, flow, and channel impellers, as well as their emergency pumping solutions, make them a versatile choice for any water management scenario. Trust in Homa Submersible Pumps to provide efficient pumping solutions for your business, backed by their expertise and commitment to excellence.

Conclusion

Homa Submersible Pumps: The Industrial Powerhouse for Water Management, are highly efficient and reliable pumps that find their application in various industries. The TP series of Homa pumps are specifically designed for industrial wastewater management, while the HOMA H300 series is ideal for pumping bilge water in the shipping and transport industry. These pumps, made with stainless steel components, are known for their durability and longevity. With the ability to handle various fluids, including those from the chemical industry, Homa pumps are a trusted choice for wastewater management. Their seal and bearing housing are designed to withstand stress and vibrations, ensuring a longer life for the pump. The discharge connectors and impeller in the CK, CVX, and CV series pumps are engineered for efficient pumping. Investing in Homa Submersible Pumps is a wise choice for any business in need of reliable water management solutions.

FAQ

What are Homa Submersible Pumps?

Homa Submersible Pumps are powerful industrial pumps designed for water management. They are fully submersible, meaning they can operate underwater for various applications.

What are the key features of Homa Submersible Pumps?

Homa Submersible Pumps are known for their energy efficiency, environmentally friendly design, durability, and long lifespan. They also have different models with unique features to suit various usage scenarios.

What are the applications of Homa Submersible Pumps?

Homa Submersible Pumps can be used for a wide range of applications, including drainage, sewage pumping, wastewater treatment, industrial processes, irrigation, and water supply in residential, commercial, and municipal settings.

What benefits do Homa Submersible Pumps offer?

Homa Submersible Pumps offer numerous benefits, such as high energy efficiency, reduced operating costs, low environmental impact, reliable performance, easy installation, and minimal maintenance requirements.

Are Homa Submersible Pumps environmentally friendly?

Yes, Homa Submersible Pumps are designed with energy efficiency and environmentally friendly features. They help conserve energy, reduce carbon emissions, and minimize the ecological footprint.

How long do Homa Submersible Pumps last?

Homa Submersible Pumps are built to be durable and have a long lifespan. With proper maintenance, they can last for many years, providing reliable performance and cost-effectiveness.

What are some common troubleshooting steps for Homa Submersible Pumps?

If you encounter issues with your Homa Submersible Pump, some general troubleshooting steps include checking power supply, inspecting for debris or clogs, ensuring proper installation, and verifying control settings.

How can I properly maintain my Homa Submersible Pump for a longer lifespan?

To ensure a longer lifespan for your Homa Submersible Pump, it is important to follow proper maintenance practices. Regularly check for signs of wear and tear, clean or replace filters, lubricate moving parts, and schedule professional inspections and servicing.

Why should I choose Homa Submersible Pumps for my business?

Homa Submersible Pumps offer superior performance, energy efficiency, durability, and versatility. They are specifically designed for industrial water management applications, making them a reliable and cost-effective choice for businesses.

Is investing in Homa Submersible Pumps an informed decision?

Yes, investing in Homa Submersible Pumps is an informed decision due to their proven track record in water management applications, their range of models to suit different needs, and their positive reputation for quality, efficiency, and durability.

What can I conclude about Homa Submersible Pumps?

Homa Submersible Pumps are an industrial powerhouse for water management. They offer a wide range of applications, unique benefits, energy efficiency, durability, and easy maintenance. Choosing Homa Submersible Pumps is a wise decision for reliable and efficient water management solutions.